Compressor History

The history of the compressor goes back to the beginnings of air conditioning systems, being since then the most important component. We remember how we started with the Packard, a system where the evaporator was at the rear of the car, and the lines crossed the entire car to reach the belt-driven compressor and condenser at the front of the vehicle. What a story! From those days to what currently exists in cars, there has been a long road, and we will detail and learn more about these advances.

Compressor Function

I always start by saying that the compressor is the heart of the air conditioning system, as it ensures that the refrigerant moves steadily through the evaporator, condenser and other components. But what happens when the compressor is not running? This is where the system cannot circulate coolant and therefore does not cool the cabin.

The main function of a compressor is to convert and move refrigerant through the air system, allowing the air inside to be effectively cooled. The compressor receives the refrigerant in a gaseous state at low pressure and raises its pressure to increase the temperature, converting it into a high-pressure hot gas. This flow is crucial, as it allows the cold, low-pressure refrigerant to be compressed, raising its pressure and temperature, and transformed into a hot, high-pressure gas. Once the refrigerant leaves the compressor, it is directed to the condenser as a hot, high-pressure gas.

Types of Compressors Used

Let’s learn a little about the most common compressors. Today, there are several known types: rotary paddle, scroll and variable scroll. Each has been revolutionary and has a different performance. Let’s learn more about them.

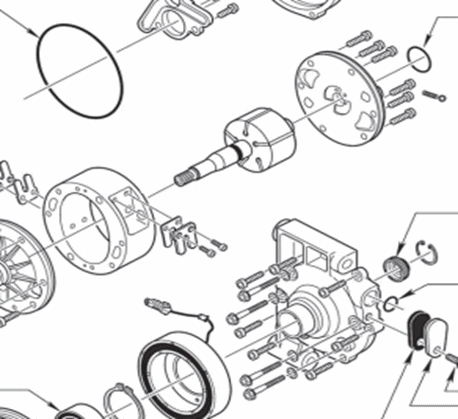

Rotary Vane Compressor

The rotary vane compressor was one of the forerunners and was noted for moving the refrigerant of

centrifugally. This type of compressor can rotate inside a cylindrical area, and during rotation, centrifugal force pulls the vanes out of the slots to create individual spaces. This allows for volume reduction and increased air pressure. It is important that this compressor is lubricated with oil for proper operation.

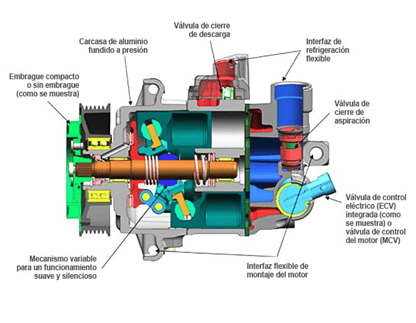

Variable Displacement Compressor

The variable displacement compressor has the particularity of adjusting the motor speed to meet the needs of the system. It can operate at 100% capacity, although it can also fluctuate to lower amounts. This has been a great relief to engine strength, as compression only occurs when necessary. In this way, the motor does not require all its power most of the time just to compress the coolant.

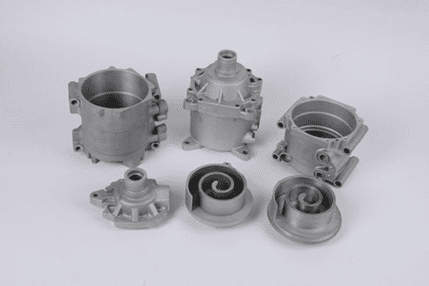

Scroll Compressor

Another great design is the scroll compressor. This compressor has a spiral rotor design that generates a continuous movement of the compressed refrigerant in several stages, achieving compression by reducing the volume. It is important to know how the scroll works, as it is the precursor of the compressors used in today’s electric cars.

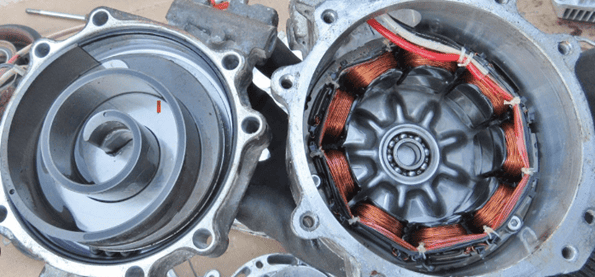

Electric Scroll Compressors

Today, electric compressors use the scroll system to compress the refrigerant and are driven by a three-phase electric motor. This allows them to be powered by the voltage coming from the vehicle’s battery, making them efficient and suitable for modern electric cars.

These types of compressors have evolved significantly and each has brought significant advances in automotive air conditioning technology.